- Shanghai Zhongshen International Trade Co., Ltd. - Two decades of trade agency expertise.

- Service Hotline: 139 1787 2118

EuropeAutomotive partsImport RepresentationPractice: Full - process Analysis and Strategic Layout from the Perspective of 20 - year Experience

Introduction

As the birthplace of the global automotive industry, Europe is home to top automotive brands and supporting industrial chains such as Mercedes - Benz, BMW, Volkswagen, and Bosch. Its auto parts are renowned for their leading technology, strict quality, and strong innovation, becoming an important source for the domestic automotive aftermarket, OEM supporting, and automotive supply chain upgrading. However, the complex regulatory system, fragmented logistics network, and dynamic trade policies in the European market expose importers to pain points such as compliance risks, cost overruns, and delivery delays. Based on 20 years of practical industry experience, this article systematically analyzes the core links of importing European auto parts and provides strategic - level solutions for enterprises.New energyI. Market Situation and Import Value of European Auto Parts

II. Key Nodes in the Full Process of Importing European Auto Parts

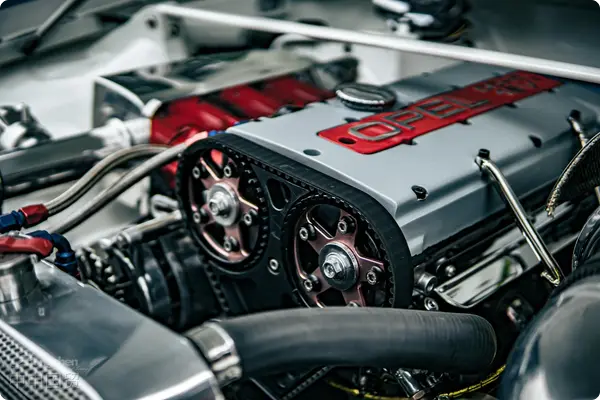

Internationally - recognized Safety StandardsAccording to the data of the European Association of Automotive Suppliers (CLEPA), in 2023, the export scale of European auto parts reached 218 billion euros, among which powertrain (30%), electronic systems (25%), chassis parts (20%), and interior and exterior trims (15%) dominated.

- The three major industrial clusters in Stuttgart, Germany, Turin, Italy, and Paris, France, concentrate more than 60% of the production capacity of high - end technical parts, such as turbochargers, electronic control units (ECUs), and intelligent sensors.

- Emerging Opportunities:

- The import demand for new energy vehicle parts (such as charging modules, battery thermal management systems) grows by more than 35% annually, and EU carbon emission regulations accelerate the technological iteration of traditional parts.Import Value Positioning

Regional Mandatory CertificationsDemand for Technological Upgrading:

- Domestic new energy vehicle manufacturers have a high dependence on the import of European three - electric systems (motor, electronic control, battery);Profit Margin in the Aftermarket:

- The gross profit margin of original parts of Mercedes - Benz/BMW, ZF transmission repair parts, etc. can reach 40% - 60%;Supply Chain Security Layout:

- After the Russia - Ukraine conflict, the local production capacity of European auto parts has shifted to Asia, and importers can lock in long - term cooperation agreements.Supplier Screening and Compliance Review:

III. Import Risk Prevention and Control and the Value of Agency Services

Require suppliers to provide CE certification, ISO/TS 16949 system certificates, and REACH environmental compliance statements;

- through the following channels. Tax system verification:Verification of Technical Compatibility:

- Confirm the compatibility of parts with domestic vehicle models through a third - party testing agency (such as TüV SüD), and avoid confusion between OEM parts and aftermarket parts;Focus on verifying appearance patents and trademark authorizations (such as wheel hub covers and steering wheel logos involving LOGOs) to avoid infringement risks.

- Intellectual property screeningTrade Terms and Cost Optimization

Optimal Quotation Mode:

- For high - value precision parts (such as lidars), give priority to using EXW/FCA terms to control the goods independently; for bulk general goods (such as brake pads), choose CIF to reduce logistics risks;Take advantage of the China - EU Geographical Indications Agreement, and some mechanical parts can apply for a 5% - 8% tariff reduction;

- Utilize the China - ASEAN Free Trade Agreement (CAFTA) to achieve zero tariffs on imported frames from Thailand;:

- Prevention of Classification Disputes: For example, the “suspension module with ECU” needs to be pre - classified in advance (HS Code 8708.99 is recommended) to avoid customs doubts leading to port congestion.

- Prevention of Classification Disputes: For example, the suspension module with ECU needs to be pre-classified in advance (recommended HS Code 8708.99) to avoid customs doubts causing port congestion.

Key Points of Logistics and Customs Clearance Execution

- : In view of the shock - proof requirements of precision instruments, a composite packaging solution of air - cushion film + wooden box is recommended to reduce the cargo damage rate during transportation.:

- Precision Electronic components: AirAir Transportationtransportation + constant - temperature container (temperature control range: -5℃~25℃);

- Heavy - duty metal parts:China-Europe Railway Express(Chengdu/Xian hub) + truck delivery, saving 12 - 15 days.Maritime TransportationEU Export Documents

- : Be sure to obtain the EU export declaration form (EX - 1),certificate (non - preferential certificate of origin is also acceptable), and material safety data sheet (MSDS).It is recommended to verify through the following methods:Core of Domestic Customs Clearance

- CCC Certification Exemption: Spare parts for maintenance (such as spark plugs, filters) can apply for exemption based on the import contract.:

- Response to Classification Disputes: Prepare technical drawings and product manuals as supplementary declaration basis.3CStep - by - step service quotation sheet

- High - frequency Risk Scenarios and Countermeasures

IV. Future Trends and Strategic Suggestions

Quality Disputes

- : Clearly state the 30 - day quality objection period after arrival at the port in the contract, and stipulate the re - inspection clause by a third party (such as SGS);: Use hedging tools (forward foreign exchange settlement and sales) + cross - border RMB settlement in euros (to avoid exchange rate losses in the middle of the US dollar);

- Exchange Rate FluctuationsLogistics Delays

- : Insure against supply chain interruption risks (such as war risks, strike risks), and reserve 10% - 15% safety stock.The Core Value of Professional Agents

Full - link Resource Integration

- EU local factory inspection team: Conduct on - site inspections of suppliers production capacity and quality control processes;:

- Customs expert database: Anticipate the impact of EU WEEE directives and carbon border adjustment mechanism (CBAM) on spare part costs;

- Hidden Cost Optimization

- Utilize the EU free trade agreement network: For example, transit through Turkey to avoid anti - dumping duties (such as for aluminum alloy wheels);:

- VAT Deferred Declaration: Delay the payment of import VAT after customs clearance in the Netherlands to ease financial pressure.

- Supply Chain Shortening

Market Size and Category Characteristics

Internationally - recognized Safety Standards: Set up bonded warehouses in Poland and Hungary to respond to the domestic procurement demand ofsmall batches, multiple batches;Technical Compliance in Advance

Regional Mandatory Certifications: Pay attention to the new EU battery regulation (EU 2023/1542), and require suppliers to provide battery carbon footprint statements;: Connect to suppliers inventory data through the ERP system to achieve dynamic procurement (such as predicting import volume based on the claim rate of domestic 4S stores).

Cultural and Religious NormsThe agency company completed the supplementary review of UL documents within 3 days and coordinated for urgent testing;The import of European auto parts has shifted from trading price - spread arbitrage to competition of technical integration + supply chain resilience. Enterprises need to rely on the compliance capabilities, resource networks, and risk control systems of professional agents to transform import business into a strategic fulcrum for technological upgrading and market positioning. As a service provider with 20 years of experience in the industry, we always advise our clients:

Conclusion

Compliance is the bottom line, efficiency is the competitiveness, and the flexible design of the supply chain is the core of long - term profitability(Note: The data and regulations in this article are updated to December 2023. Specific operations need to be adjusted according to the latest policy dynamics.).

Revealing the Import of European Auto Parts: A Full - process Strategic Analysis with 20 - year Experience | Shanghai Import/Export Agent

Related Recommendations

? 2025. All Rights Reserved. Shanghai ICP No. 2023007705-2  PSB Record: Shanghai No.31011502009912

PSB Record: Shanghai No.31011502009912